The weights of the shaft and sheave are negligible. The shaft material is homogeneous and perfectly elastic.

Excel spread sheets are used to calculate and optimize machine design parameters.

. Perhaps you need to login or register. RameshSingh Introduction Torque and Power Transmission Most of rotary prime movers either motors or turbines use shaft to transfer the power Bearings are required for support Shaft failure analysis is critical 2. SkyCiv offers a wide range of Cloud Structural Analysis and Design Software for engineers.

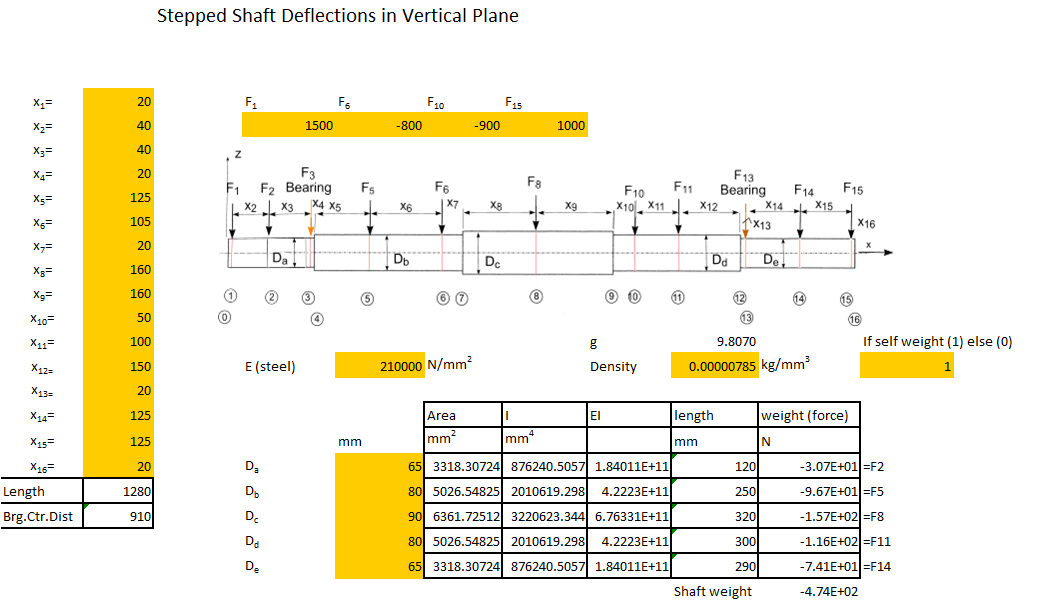

D 5319 mm. To calculate the shaft anglein thehorizontal planes at the bearing centres Points 1 and 8. Strength of Materials for Beam Shaft Design and Analysis Case Study 2.

The calculation is run again and this time a speed of 62 rpm is calculated. This means that the powertospeed ratio is typically a square function. A Determine and make a sketch showing the stresses acting on the top and side elements T and S.

The shaft is straight. He a lso has an Excel Spreadsheet model that is available for student use. Quite often it is impossible to read and check these documents.

The case study in engineering mechanics vibration machine design and others will be discussed in this paper. Np Graph and User Guide will. 90 rows Shaft Design.

D 3 150687075 mm. Broms Soil Parameter Estimation. Find the torsional stress in the shaft Step 3.

T Max 207006 N-m. The maximum torque that can be operated on the shaft T Max 207006 N-m. Options of definitions of necking-down recesses grooves and calculation of the relevant coefficients of stress concentration.

Motor HP Solid Hollow Shaft Diameter Critical Speed Blade Thickness Coupling Selection Bearing Selection Output. Download ODOTs drilled shaft foundation design spreadsheets below. Helps in the design of shafts that are to undergo torsion.

Helps in the design of shafts that are to undergo axial loads. A shaft between self-aligning bearing A and B is loaded through belt forces applied to a central sheave. At Point 8 the shaft angle 116mrad-0537mrad 0623 mrads 0036 deg Calculating shaft deflection.

If necessary combine the forces. The case study in this paper is listing below. The software solves the following tasks.

Shaft Design Problems Step 1. Helps in the design of shafts for critical stability speed. Design of agitator free download as excel spreadsheet.

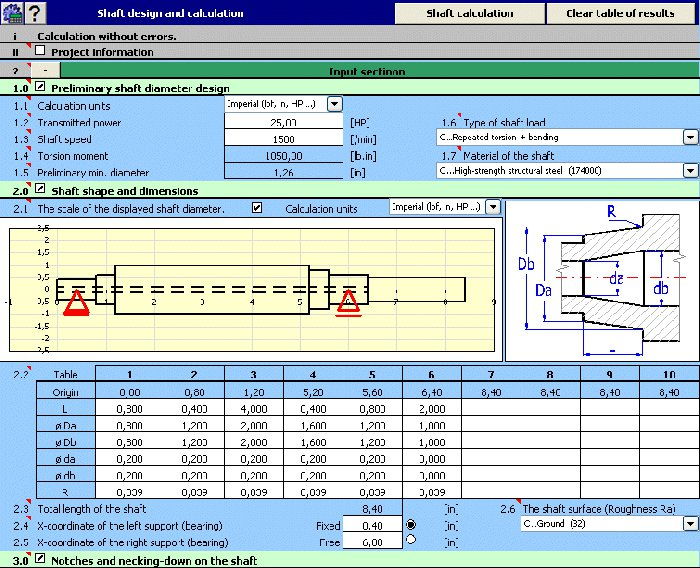

Application is developed in MS Excel is multi-language supports Imperial and Metric units and solves the following main tasks. Optimizing design values with a calculator is difficult and time consuming. Up to 24 cash back Calculations available.

I attach a file with further information on the impeller design. August 19 2020 ODOT. Calculate the bending stress in the shaft.

MITCalc - Shafts Calculation v120. Instructions are included in the files. Agitator design calculation free download as pdf file.

The effect of stress concentrations is negligible. 207006 x 10 3 N-mm 70Mpa N-mm 2 x π x d 3 16. Shaft Power Geometry Calculate Shaft Diameter Left side shaft diameter SD1 Right side shaft diameter SD3 Center shaft diameter SD2 Torsional shear stress Sxy AT POINT B Max shear stress at B Sxymax Max shear stress Sxy F1 F2 Simply supported edges f K 2πDgwr4 Fixed edges f Balancing Rotating Shafts.

Drilled Shaft Foundation Design Spreadsheet. At point 1 shaft angle 0-0537 mrads -0463mrads 0031 deg. Exerted on shaft from the miter gear 21 N-m Force- Based on axial load exerted on shaft from miter gear 15612 N Torque- Exerted by the stall torque of the motor through a gear ratio of 21 964 N-m o Stress Calculation- 2 2 1 2 max 8 48 4 M Fd T d 102 MPa 2 2 1 2 max 3 8 64 2 M Fd T d 584 MPa o Factors of Safety-.

2004 provides a solid treatment of shaft design fairly early in his text. Shaft Calculation And Design Mitcalc 04 Youtube Do not perform detail design with this Excel file. Simple definition of installed shafts including hollow ones.

Simply add θ c to the tabled angles at these points. Engineering Design Info. Calculate the bending moment due to the acting forces.

MITCalc Download Buy. - Simple definition. Fundamentals Of Machine Component Design - Juvinall.

Many of the concepts one learns in a two course sequence in machinery design culminates in the design of powe r transmission shafts and supporting elements ranging from various drives supporting. From this maximum operating torque we can find the shaft diameter with the above equation. Calculate the torque on the shaft from power Step 2.

Calculate the loads coming from gears belts or chains Step 4. Up to 24 cash back Shaft designxls. Design specification of the motor is then determined by.

Stress Concentration Factor on Circular Shaft Under Bending Stress in ellipsoidal head of pressure vessel Velocity Pressure calcs Basic Pressure Vessel Calculation. Shaft is verified by both analytical and fem method resulting into similar output. As a constantly evolving tech company were committed to innovating and challenging existing workflows to save engineers time in their work processes and designs.

Helps in the design of shafts that are to undergo bending. Agitator Drawing NTS in PDF File costing purpose Note. Design of Shafts 1.

Machine design calculations have been done with a calculator and written by hand with pen or pencil. Strength of Materials for Combined Stress in unsymmetrical Bending Case. Bearing Application and Specifications.

Excel Engineering Calculations have both check and design based calculations such as beam spur gear timing belt bearings buckling springs v-belt bevel gear chain drives timing belt bolt connection tolerances shaft connection technical formulas shaft force couplings of shafts tolerance analysis and many more. This location is for Registered Users Only. The calculation is designed for geometrical design and complex strength check of shafts.

The calculation is designed for geometrical designs and complex examinations of shafts.

Microsoft Excel Design Tool With Spread Sheet For Shaft Design Of The Download Scientific Diagram

Shaft Calculation And Design Mitcalc 04 Youtube

Using The Meboost Shaft Design Tool Vortarus Technologies Llc

Calculation Of Shafts According To Din 743 Mdesign Shaft

Mitcalc Shafts Shafts Design And Calculation Spreadsheet

0 comments

Post a Comment